Flexography is useful today in many industries, for packaging or even for publishing books and newspapers. The history of flexo printing begins in 1890, when it was called aniline printing. Although it was used for 500 years in food packaging, in 1940s things were about to change.

The Food and Drug Administration has classified aniline ink as being toxic. Some years later, the flexography regained its importance and nowadays are many printing companies that use flexo-printers.

A database of flexo printers can provide you all the information you need about the numbers of companies that offers these kinds of services. Flexography has been greatly used over time, due to its versatility. It is economic and can be easily used to create packaging from different materials, such as paper or plastic container or metal foil. It is also used in newspaper printing presses.

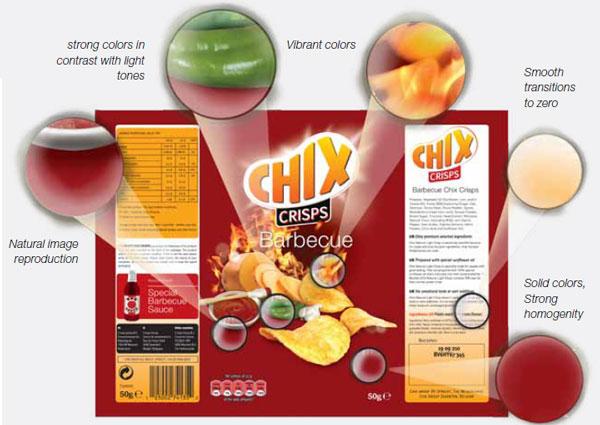

So, one of the most important advantages of flexography is the great quality of printing on a wide range of substrates. It surely can be considered an alternative to offset printing, because it is less expensive. The printing machines are cheaper and the consumable costs are lower. The reduced costs lead to attracting a greater number of consumers, causing an improvement in business.

Companies can print images with quick drying ink. The type of ink can be chosen depending on the type of material used. Before the appearing of flexography, the letterpress technology used water-based ink requiring more time to dry. Although there were commercial dryers, it involved additional costs.

Therefore, flexographic printing is the most convenient, because it involves wide types of ink and quick drying. If you want to print on cardboard or paper, you can use water-based inks, but solvent-based solutions are suitable for plastics and wallpapers.

Another important advantage of flexography is the productivity, so with only one template it is possible to print millions of images. There is no need the restructured the plate created during the printing process. It is very convenient if you intend to print a huge number of images at low cost. Also, flexography allows you to create solid colors on porous as well as non-porous substrates.

It can be used in packaging without affect the safety of consumers, so flexo printing offers multiple advantages. Are you the owner of a small business of printing, but you doing not have the equipment necessary to provide your customers with flexo-printing services? However, you believe that it would be ideal for you to be able to offers flexography solution for your customers. Than you can do only one thing!

Buy a database of flexo printing to find out the names of the main companies in the flexography. Try to collaborate with of these companies and satisfy your customer. It is an efficient and less expensive way to improve your services. You only have to access the website Printing-Companies.org to get more information about the use of databases. You will know how to make your business stronger.